The LED market is sitting tight on its upward curve at the moment, with huge predictions in terms of revenue expected in the coming years. However, this trend could easily be derailed if the initial purchase price of LED lights remains high or consumers perceive there is a problem with reliability.

We’re seeing fierce price competition across all sectors of the LED market. In many instances this is forcing designers to adopt cheaper components. This is a mistake. Using cheaper components brings with it the inherent risk of compromised products; lower light quality, reduced lifespan, and the potential for reputational damage to a young industry.

A better approach to using cheaper components to save money, especially in the HB-LED (High Brightness LED) market, lies in better thermal management. Clever design incorporating innovative, emerging thermal management technologies holds the potential to radically lower the prices of certain classes of LED lighting products.

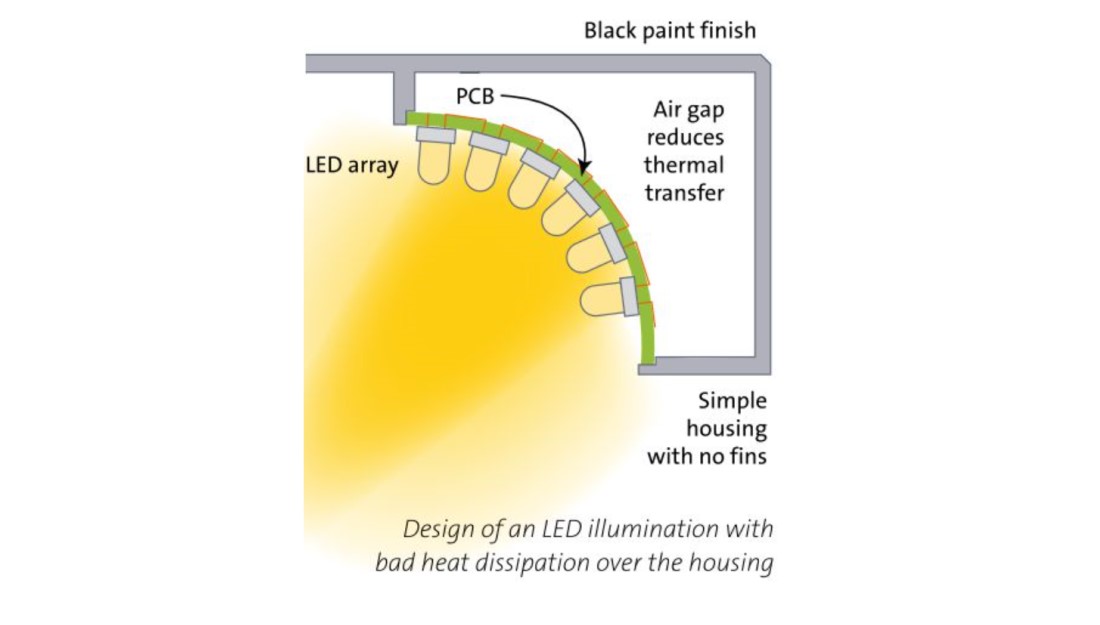

In an LED light, the semiconductor chips can account for as much as 60 percent of the BOM (Bill of Materials). If a business could halve the number of LEDs, running the remaining LEDs at higher power to achieve the same Lumens output, that business could obviously make a significant saving.

In many designs of HB-LED lights the semiconductor chips reach a thermal limit before they reach their electrical limit. If the thermal demands can be met, the economics are very attractive. Even if the improved thermal management involved a small added cost, say 5 percent, a business would still save 25 percent on its overall BOM in this scenario – a highly desirable figure in the current environment.

The traditional approach to conducting heat away from LEDs is to use Metal Clad Printed Circuit Boards (MCPCBs). These are essentially an aluminium panel coated with about 75 to 300 microns of epoxy resin to act as a dielectric layer. The resin is filled with ceramic particles to improve its through-thickness thermal conductivity. Unfortunately this approach is reaching its technological limit. Epoxy resins cannot currently be made any thinner without losing workability, or filled with more ceramic as this reduces fracture toughness and causes loss of adhesion.

In other words, we’re at an impasse. The shortcomings of available MCPCBs are limiting the industry’s ability to achieve significant cost reduction through cutting the number of LEDs in a design.

However, a radical new approach to tackling the LED heat extraction impasse has been discovered that makes use of nanoceramics.

A process has been developed to convert the surface of aluminium panels to a dense, adherent layer of aluminium oxide, possessing a nanocrystalline grain structure (an alumina nanoceramic). This process creates a dielectric layer as thin as 3 microns with thermal conductivity in the region of 7W/mK. The combination of the thin dielectric, with good thermal conductivity, gives a 20 percent thermal improvement over any commercially available MCPCB. The thickness of the nanoceramic dielectric layer can be set to meet industry breakdown voltage requirements. Because the boards are essentially panels of aluminium they can be slotted into existing PCB fabrication lines, so there are no additional costs associated with changing the manufacturing process.

In recent tests HB-LEDs mounted on a nanoceramic MCPCB ran 34°C cooler than on a standard MCPCB, resulting in slightly more Lumens being produced for the same electrical input. More importantly, this result opens up the design space and the possibility of decreasing the number of LED die by running each closer to its maximum electrical rating. This is the kind of radical improvement that is required if the LED industry is going to continue to push the limits of High Brightness LEDs.