Almost every industry, business and municipality has a parking lot that needs night-time illuminating. As energy costs continue to soar and strict energy mandates are enforced, municipalities and private property owners are looking for ways to cuts costs.

Fortunately, energy is a very controllable operating expense; by prudent, energy efficiency investments, operating costs can be reduced. One key to making day-to-day operations more energy efficient and more sustainable is through the installation of exterior LED luminaires.

Retail Centers – Retail stores, shopping malls and entertainment complexes are major energy consumers. Malls, “big box” mega-stores and retail outlets are not usually considered energy intensive on a square foot basis, but because of their large size and long hours of operation, they often run up extensive energy bills.

The parking lots for these facilities represent a challenging environment for lighting solutions. The lighting must accommodate vehicular and pedestrian traffic, endure harsh environments and address public safety considerations.

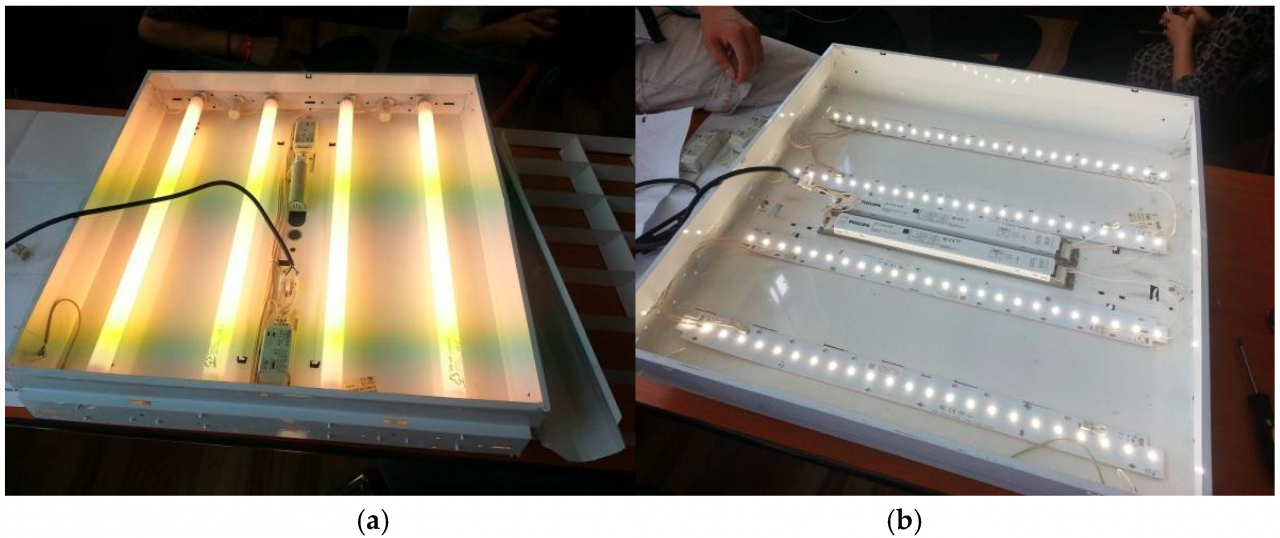

Image depicts TopDek in a typical retail parking application

Parking Lots and LED Luminaires – Going green is an initiative that nearly every industry is being forced to consider. The desire to incorporate new technologies to meet green initiatives and lessen costs is driving unprecedented change. Outdated light fixtures are being replaced with parking lot luminaires designed specifically for energy efficiency and sustainability. And while the upfront cost of LED luminaires is typically more than traditional lighting systems, it will be paid back to owners in lower electric bills, reduced maintenance and disposal fees.

Many parking lots are illuminated with high intensity discharge (HID) lighting sources. Because this type of lighting is not suitable to frequent switching, this lighting is typically operated the entire evening, even when the parking lot is mostly or completely empty. LED luminaires, however, are amenable to control systems such as motion sensors to further reduce electricity consumption.

The opportunity for savings is enormous, in part because LED luminaires have the potential to control the LED source emission more precisely than traditional HID luminaires, reducing waste light and limiting glare.

An innovative program, the Partners in Project Green in partnership with the University of Toronto’s Center for Landscape Research, offers companies (in the Pearson Eco-Business Zone) a Green Parking Lot Program. Specifically, it provides companies assistance in the (re)design of their parking lots and landscaping to include green features that can help them reduce costs, enhance safety and enrich the aesthetics of the facility, while improving local air and water quality. Installing LED luminaires is an excellent complement to this forward-thinking program.

Exterior lighting has three primary functions – safety, security and ambiance. With sustainability and design now complementing each other, LED luminaires for outdoor general lighting provide a win for everyone and retail properties retain their aesthetic integrity while saving on energy and maintenance.

Importance of Color Rendering and Distribution – Mall parking lot lighting represents a critical component for a business to achieve a high retail sales volume. Businesses must provide shoppers with safety and optimal visibility.

Color rendering should be considered as an important lighting performance element to showcase a business’ storefront displays, outdoor exhibits and landscaping features that create an aesthetically pleasing environment throughout the general grounds surrounding the mall itself.

Parking lots around malls experience a high volume of pedestrian traffic, and vehicular traffic tends to increase as closing time approaches. It is necessary for a business to provide appropriate lighting performance to insure a safe and comfortable environment is maintained.

Many cities have lighting mandates for parking lot illumination that identify a specific set of lighting performance metrics. Unfortunately, many businesses might not be aware if their parking lot lighting performance levels have fallen below minimum acceptable levels, which happen when lamps deteriorate over an extended period of time.

Distributing light and containing it within the property’s boundaries are essential components to remaining in compliance with regulatory codes pertaining to dark skies and energy efficiency.

The size and layout of the parking lot determine the specific lighting performance requirements. For example, if the parking lot is asymmetrical and located in a less safe part of town, the need for security may require a bright perimeter of light that is focused on the edges and corners of the lot while simultaneously contained within the property line.

Parking Lot Safety – Security professionals have long known that locations where people and their valuables are together, such as in parking lots, are criminals’ favorite targets. A key element of security in most surface lots is visibility – for employees, customers and passers-by; and a significant part of visibility is lighting.

According to Witherspoon Security Consulting, the exterior lighting should enable parkers and employees to see individuals at night at a distance of 75 feet or more and to identify a human face at about 30 feet. Employees who are working after-hours or visitors entering the building at night need to have efficient parking lot illumination fixtures so they can safely return to their vehicle.

Proper lighting creates better security and the perception of security, which can increase patronage of the parking facility, individual stores and the area in general.

Mindwave Research of Austin, Texas, conducted a survey, which showed that LEDs’ bright white light can help improve public feelings of safety in city spaces. After the addition of LED luminaires in a Raleigh, NC, municipal parking garage:

- Both men and women felt significantly safer post-installation: 74 percent rated the garage as feeling “very safe,” while only 2 percent did not feel safe.

- These figures contrast with the pre-installation numbers: Only 42 percent felt “very safe” with the original lighting, and 13 percent did not feel safe.

Opportunity – In the United States alone, it’s been determined there are more than 20 million parking lot lights, providing an excellent opportunity to retrofit with LED luminaires for increased security, reduced energy consumption and lowered maintenance costs.